Batch Silikoni ti PA ti o da lori dinku iye ti ija ati imudara resistance yiya

PA Based Silicone Masterbatch dinku iye ti ija ati imudarasi resistance yiya,

ati dinku akoko iyipo, kikun m ti o dara julọ, yiyọ oju ilẹ ti o dara julọ, ìtújáde m tó rọrùn jùlọ, ìmọ̀lára ọwọ́, Ṣíṣàn yíyọ́ tí ó dára síi, Dara si ibere ati yiya resistance, lilo agbara ti o dinku, Ìṣọ̀kan ìfọ́mọ́ra tó kéré síi, iyipo extruder kekere, Batch silikoni ti o da lori PA, idinku titẹ die & die dr,

Àpèjúwe

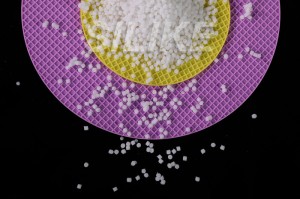

Silicone Masterbatch (Siloxane Masterbatch) LYSI-307 jẹ́ àgbékalẹ̀ tí a fi pelletized ṣe pẹ̀lú 50% ultra high molecular weight siloxane polymer tí a fọ́nká nínú Polyamide-6 (PA6). A ń lò ó ní gbogbogbòò gẹ́gẹ́ bí afikún ìṣiṣẹ́ tí ó munadoko nínú ètò resini tí ó bá PA mu láti mú kí àwọn ànímọ́ ìṣiṣẹ́ sunwọ̀n sí i àti láti yí dídára ojú ilẹ̀ padà.

A fi wé àwọn afikún moleku kékeré ti ìbílẹ̀ bíi epo silikoni, omi silikoni tàbí àwọn polymer silikoni mìíràn, a retí pé SILIKE Silicone Masterbatch LYSI series yóò fúnni ní àǹfààní tó dára síi, fún àpẹẹrẹ. Ìyọkúrò skru díẹ̀, ìtújáde máàlú tó dára síi, dín ìdàrúdàpọ̀ kú kù, ìṣọ̀kan ìfọ́mọ́ra tó kéré síi, ìṣòro kíkùn àti ìtẹ̀wé tó dín kù, àti onírúurú agbára iṣẹ́ tó gbòòrò.

Awọn Pílánẹ́ẹ̀tì Pàtàkì

| Ipele | LYSI-307 |

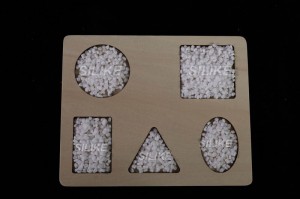

| Ìfarahàn | Pẹ́ẹ̀lì funfun |

| Àkóónú Silikoni (%) | 50 |

| Ìpìlẹ̀ resini | PA6 |

| Atọka Yo (230℃, 2.16KG) g/10min | 36.0 (iye deede) |

| Ìwọ̀n % (w/w) | 0.5~5 |

Àwọn àǹfààní

(1) Mu awọn ohun-ini iṣiṣẹ dara si pẹlu agbara sisan ti o dara julọ, idinku drool extrusion, iyipo extruder ti o kere si, kikun imuda ati itusilẹ ti o dara julọ

(2) Mu didara oju ilẹ dara si bi fifọ oju ilẹ, dinku Coefficient ti ija.

(3) Ifarapa ati resistance fifẹ nla

(4) Yiyara iṣẹ-ṣiṣe, dinku oṣuwọn abawọn ọja.

(5) Mu iduroṣinṣin pọ si ni afiwe pẹlu iranlọwọ iṣiṣẹ ibile tabi awọn epo-ọra

Àwọn ohun èlò ìlò

(1) Àwọn àdàpọ̀ PA6, PA66

(2) Àwọn àdàpọ̀ okùn dígí PA

(3) Àwọn pílásítíkì ìmọ̀-ẹ̀rọ

(4) Àwọn ètò mìíràn tó bá PA mu

Bí a ṣe le lò ó

A le ṣe ilana masterbatch silikoni jara SILIKE LYSI ni ọna kanna bi ohun ti n gbe resin ti wọn da lori. A le lo o ni ilana idapọmọra yol kilasika bii Single / Twin skru extruder, injection molding. A gba ọ niyanju lati lo adalu ti ara pẹlu awọn pellets polymer wundia. Fun abajade ti o dara julọ, a gba ọ niyanju lati gbẹ ṣaaju fun wakati 3 ~ 4 ni iwọn otutu 80 ~ 90 ℃.

Ṣe iṣeduro iwọn lilo

Nígbà tí a bá fi kún PA tàbí thermoplastic tó jọra ní 0.2 sí 1%, a retí pé kí a mú ìṣiṣẹ́ àti ìṣàn resini náà sunwọ̀n síi, títí kan kíkún mọ́ọ̀dì tó dára jù, agbára extruder díẹ̀, àwọn lubricants inú, ìtújáde mọ́ọ̀dì àti ìṣiṣẹ́ tó yára jù; Ní ìpele àfikún tó ga jù, 2~5%, a retí pé kí àwọn ànímọ́ ojú ilẹ̀ sunwọ̀n síi, títí kan ìpara, ìyọ́, ìwọ̀n ìfọ́pọ̀ tó kéré síi àti agbára ìfarapa tó pọ̀ síi

Àpò

25Kg / àpò, àpò ìwé iṣẹ́ ọwọ́

Ìpamọ́

Gbé e lọ gẹ́gẹ́ bí kẹ́míkà tí kò léwu. Tọ́jú sí ibi tí ó tutù tí afẹ́fẹ́ sì ń fẹ́ dáadáa.

Ìgbésí ayé àwọn ohun èlò ìpamọ́

Àwọn ànímọ́ àtilẹ̀wá náà wà ní ipò tó yẹ fún oṣù mẹ́rìnlélógún láti ọjọ́ tí a ṣe é, tí a bá tọ́jú wọn sínú ibi ìpamọ́ tí a dámọ̀ràn.

Chengdu Silike Technology Co., Ltd is a manufacturer and supplier of silicone material, who has dedicated to R&D of the combination of Silicone with thermoplastics for 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnSilike silicone masterbatch LYSI-307, PA Based Silicone Masterbatch, used as an efficient agent in PA resins and glass fiber-reinforced PA compounds, significantly reduced the coefficient of friction and improved wear resistance at lower loadings than PTFE while retaining important mechanical properties. It also additives in processing efficiency and improves material injectability. Besides, helps finished components deliver scratch resistance while enhancing surface quality. In contrast to PTFE, silicone additive avoids the use of fluorine, a potential medium- and long-term toxicity concern. as well as silicone additive comes with doing something environmentally sound.

Àwọn afikún silikoni ọ̀fẹ́ àti àwọn àpẹẹrẹ Si-TPV tó ju àwọn ìpele 100 lọ

Irú àpẹẹrẹ

$0

- 50+

Awọn ipele Silikoni Masterbatch

- 10+

awọn ipele Silikoni Lulú

- 10+

Awọn ipele Anti-scratch Masterbatch

- 10+

Awọn ipele Anti-abrasion Masterbatch

- 10+

awọn ipele Si-TPV

- 8+

awọn ipele Silikoni Wax

-

Foonu

-

Imeeli

-

Whatsapp

Whatsapp

-

Òkè

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur